AIM’s servo feed retrofit system – which is independent of the mechanical Reeves drive, clutch, and segment – provides the ultimate feed control. The motion profile of the feed ratios with the mechanical cam shaft using encoder feedback. An operator interface is used for inputting feed values based on degrees of camshaft rotation.

Features/Benefits

- Programmable servo feed axis for single, multiple, and bi-directional feeds

- Programmable stop on sensor for length and angular control

- Minimum backlash for high accuracy

- Eliminates segment, clutch drive, and change gears

- Servo feed is electronically coupled to camshaft

- Shutdown inputs for dereeler and external length gauge

Advantages

High Accuracy

Segment arm and one-way feed clutch are eliminated.

Reduced Setup Time

Feed change gears and mechanical adjustments are no longer required, and feed can be programmed around set cam positions.

Flexible Feed

Single, multiple, and bi-directional feed.

High Torque

Continuous high torque available for all wire diameters and feed lengths.

Higher Production Rates

The need to cycle the segment arm is eliminated. Programmable feed velocity and accelerations yield higher production rates.

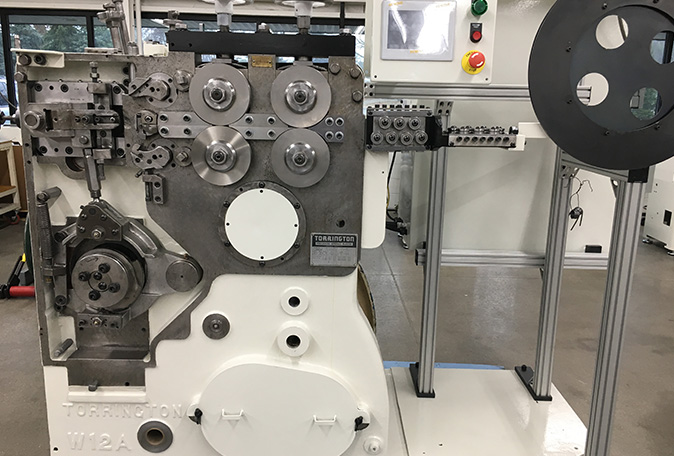

Standard Models Available: Torin W100, Torin W10A, Torin W11A, Torin W115, Torin W12A, Torin W125’s, Torin W13A

Other retrofit packages are also available.

Need help?

Our experts can help you find the best solution for your manufacturing need.

W10A Coiler

W12A Coiler