Automated Solutions for Solenoid Manufacturing

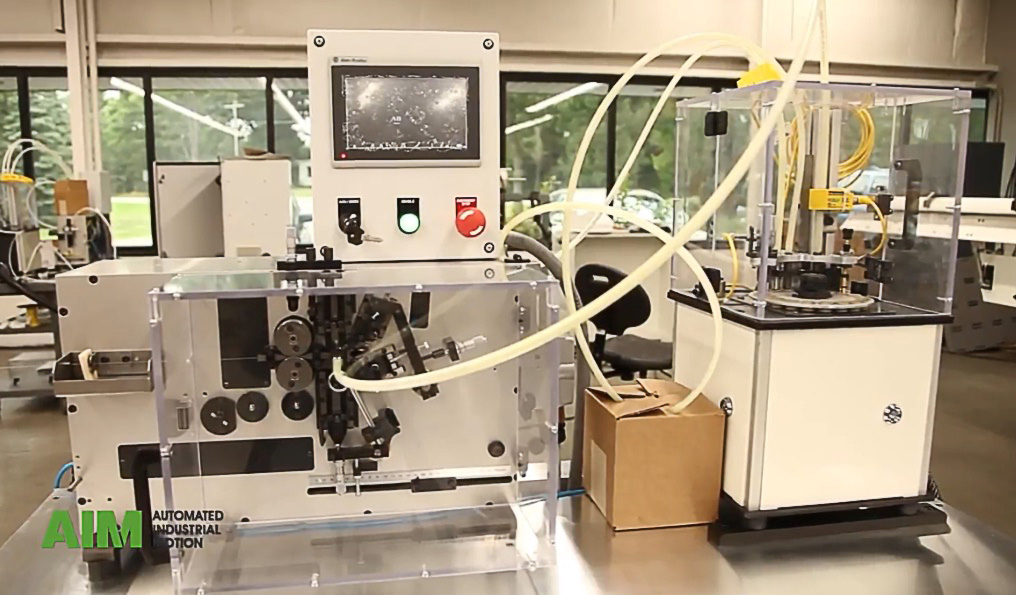

In order to provide a customer with an automated solution for solenoid manufacturing, we designed and implemented a full-service system based around our AIM 100 Pneumatic Coiler.

The pneumatic version of the AIM 100 spring coiler is a more cost-effective option for manufacturers who don’t need the customization and CNC controls offered by our standard line of spring coilers. We combined the pneumatic coiler with a power dereeler, inductive stress relief and in-line quality control. With the push of a button, the manufacturer can send wire in one end of the system and produce finished, stress-relieved, quality-tested springs at the other.

This coiler setup is intended for on-demand production of specific springs. Material is fed from a powered wire dereeler into a pneumatic coiler. The spring is produced with one stroke of a pneumatic cylinder. Pneumatic power creates quick, efficient and consistent coiling. Once the spring is made, it is carried away by an air tube and dropped into a rotary table to be stress relieved. The system then automatically performs spring set operations, then checks length and load. Good springs feed directly to an automated assembly station, while non-conforming springs fall into a scrap bin.

To learn more about our setup for producing return springs for automotive solenoids, read our blog post or watch the video below.