Spring Coiling Solutions for Healthcare and Medical Device Technology

Many medical devices, including implantable cardiovascular devices like pacemakers, as well as technologies such as insulin pump systems and closed IV catheters, rely on coils. Many medical devices require small-diameter wires that are both precise and reliable enough to ensure long-term performance. Our in-line solutions allow medical device manufacturers to automate coiling, stress relief, quality testing and assembly into medical devices, even with high production volumes.

AIM solutions for medical device coiling

Automated Industrial Motion (AIM) provides customized medical wire coiling solutions that meet or exceed the design standards required by OEMs in the medical device industry. Medical devices often require springs and coils made from small-diameter wire, designed to meet a variety of parameters in terms of performance, longevity and material safety. Our versatile automation systems leverage our expertise in spring coiling machines, wire forming equipment and other specialized machinery.

AIM’s comprehensive automation systems are capable of:

- producing springs and coils on demand, including stress relief;

- integrating with assembly lines for automated manufacturing;

- eliminating issues with bowl feeding and spring tangling;

- achieving cost savings through vertical integration of spring making;

We set up, program and test our turnkey automation solutions before delivery, allowing our customers to get up and running as quickly as possible. We provide training resources and the support needed to ensure minimal downtime during coil production.

CONTACT US TODAY FOR A QUOTE

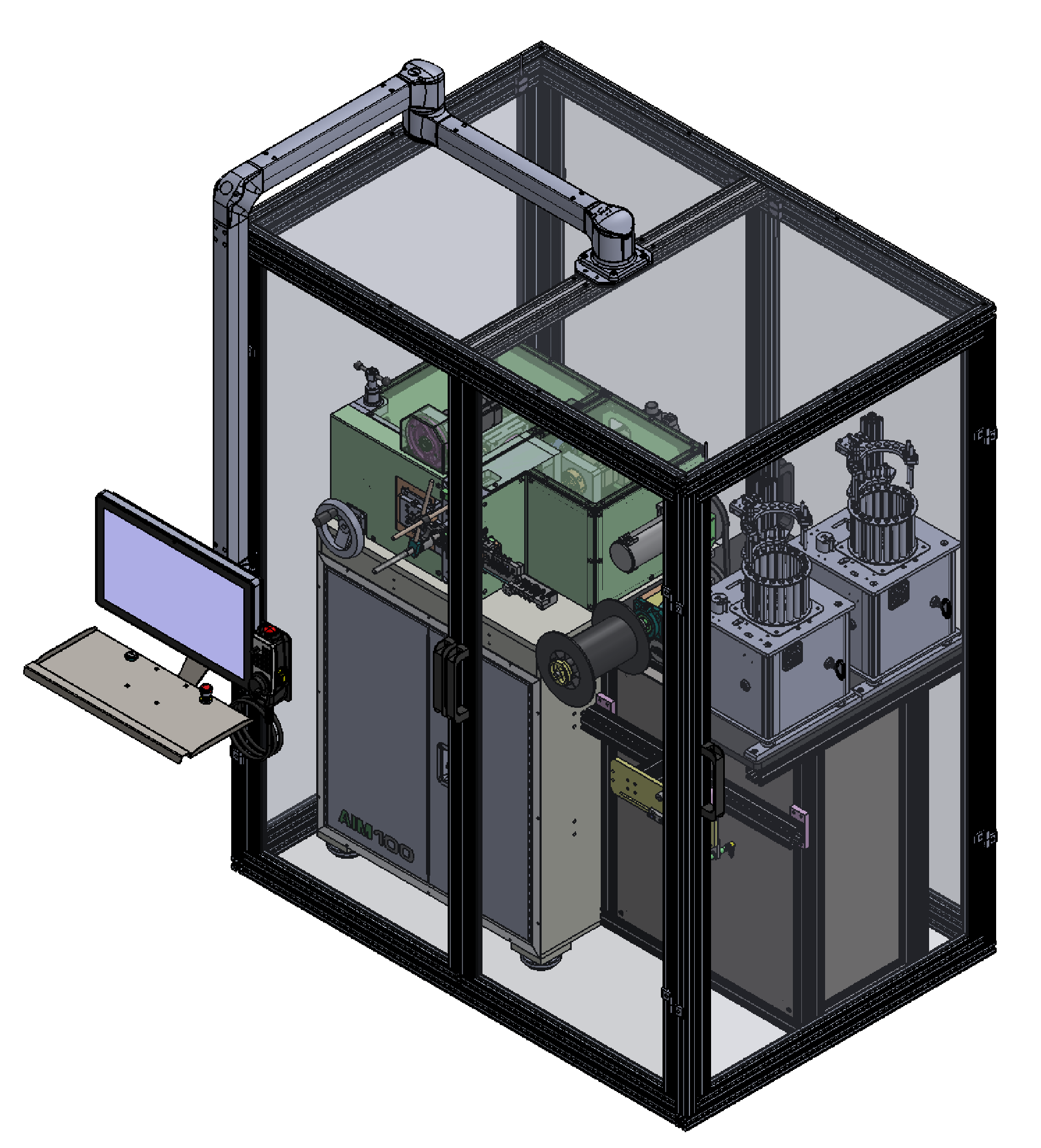

AIM 100 automation coiler with attached stress relief system

The AIM 100 is our smallest CNC model, engineered to achieve maximum precision and accuracy in coiling small-diameter wire. With its advanced design, the AIM 100 technology allows for the manufacture of custom medical coils with extremely tight tolerances, meeting even the most challenging design specifications. This coiling machine is also easy to integrate with assembly line systems, and can be configured to coil, heat treat, test for quality and deliver springs to the assembly point.

Our recommended manufacturing setup integrates spring coiling with stress relief and quality control into a single cell. This start-to-finish solution allows manufacturers to coil springs, stress relieve the springs through resistance heating, and automate quality control for precise spring size and shape. The cell can then be integrated with new or existing automation processes for full assembly.

Our AIM 100 automation coiler features a wire size range from 0.006” to 0.032,” a maximum feed speed of 135” per second, unlimited feed length, and a coil diameter range from 3 index to 1.0”, operating on 240 volts of power. Like our other CNC spring coilers, it is controlled through a Windows-based industrial touchscreen, and offers up to six axes, direct servo drives, AC brushless servomotors and high precision actuators.

The stress relief system linked to the AIM 100 improves the durability and performance of springs by reducing residual stresses. This leads to fewer defects and ensures that the behavior of the springs remains consistent over time, guaranteeing reliable functionality and dependability.

With its diverse customization options and the flexibility provided by its wire diameter range, together with the attached stress relief system, the AIM 100 automated coiling system is the ideal setup for manufacturing high-quality precision springs for medical devices. Springs produced by our AIM 100 coiler are already integral components in a variety of medical equipment including reinforced tubing, catheters, guidewires, syringes, retractable needle technology, and drug delivery devices.

Watch the AIM 100 automation coiler produce medical device compression springs at a production rate of over 100 PPM.

CONTACT US TODAY FOR A QUOTE

What are medical coils, and how do they improve patient care?

Medical coils are a type of spring used in manufacturing medical devices, available in various sizes to support a wide range of medical processes. Among the variations are small wire coils. These small-diameter coils are crucial for specific medical applications, especially parenteral administration devices used in minimally invasive procedures like catheter insertion and drug delivery systems. The importance of medical coils lies in addressing a key challenge for medical professionals: conducting invasive procedures with minimal discomfort for patients. For this reason, wire coiling plays an important role in advancing medical technologies focused on improving patient care.

To manufacture medical coils, it’s essential to partner with a manufacturer with the highest level of specialized expertise and precision equipment. Our versatile AIM 100 automated coiling system has been put to the test across numerous applications, and excels in producing compression springs for medical devices.

Automation systems for medical coil manufacturing

In medical coil manufacturing, the AIM 100 automated coiling system stands out for its exceptional compactness and performance. Integrating stress relief into the spring manufacturing process not only enhances coil strength and consistency but also extends their lifespan, underscoring the critical role of automation systems in advancing medical device production.

Watch our video to see how inline stress relief works.

Automated Industrial Motion: Your supplier for medical coiling equipment

At Automated Industrial Motion, we take pride in supplying high quality, American-made spring coiling machines and wire forming equipment. Our extensive manufacturing experience equips us with a firsthand understanding of coil production optimization for many situations. You can count on us as your dedicated experts in producing medical coils, leveraging our knowledge and experience to deliver superior solutions.

Specialist expertise working on a small scale

AIM specializes in turnkey coiling systems and custom-designed wire forming machinery. We tailor our systems for manufacturers requiring unique spring coiling and wire forming solutions that significantly improve productivity. Our top-selling AIM 100 CNC coiler, equipped with stress relief technology, offers extensive customization options and unparalleled versatility.

Customers in the medical device industry choose us because of our specialized machinery, comprehensive capabilities and understanding of stringent medical device standards. You can trust our coiling machines to coil, stress relieve, test and organize high-precision coils with the quality necessary for medical devices. Whether it’s coils for closed IV catheter systems, retracting syringes, guidewires, or other intricate medical applications, our systems can be tailored to produce small coils with precision and consistency.

AIM manufacturing and turnkey solutions

Automated Industrial Motion (AIM) specializes in producing custom medical coiling systems through collaborative design with our customers. Our Michigan-based company is able to supply OEMs and automation companies with some of the highest quality medical coiling systems on the market.

We offer automation solutions for on-demand production of springs and coils, eliminating frustrations like bowl feeding and spring tangling. Our in-line spring coiling cells can be easily integrated into assembly processes. We utilize advanced 3D modeling and CAD/CAM software to design and build cassette tooling tailored to each customer’s unique requirements. For companies looking to achieve cost savings through the vertical integration of spring making, AIM coiling systems are an easy answer.

Our turnkey solutions include pre-shipping equipment tooling, as well as programming, setup and testing. Additionally, we provide training resources to help our clients maximize efficiency and productivity.

At AIM, we are committed to delivering efficient and effective manufacturing solutions to our clients. To find out more how our expertise can help to improve your upcoming medical device design project, Contact Us or Request a Free Quote.