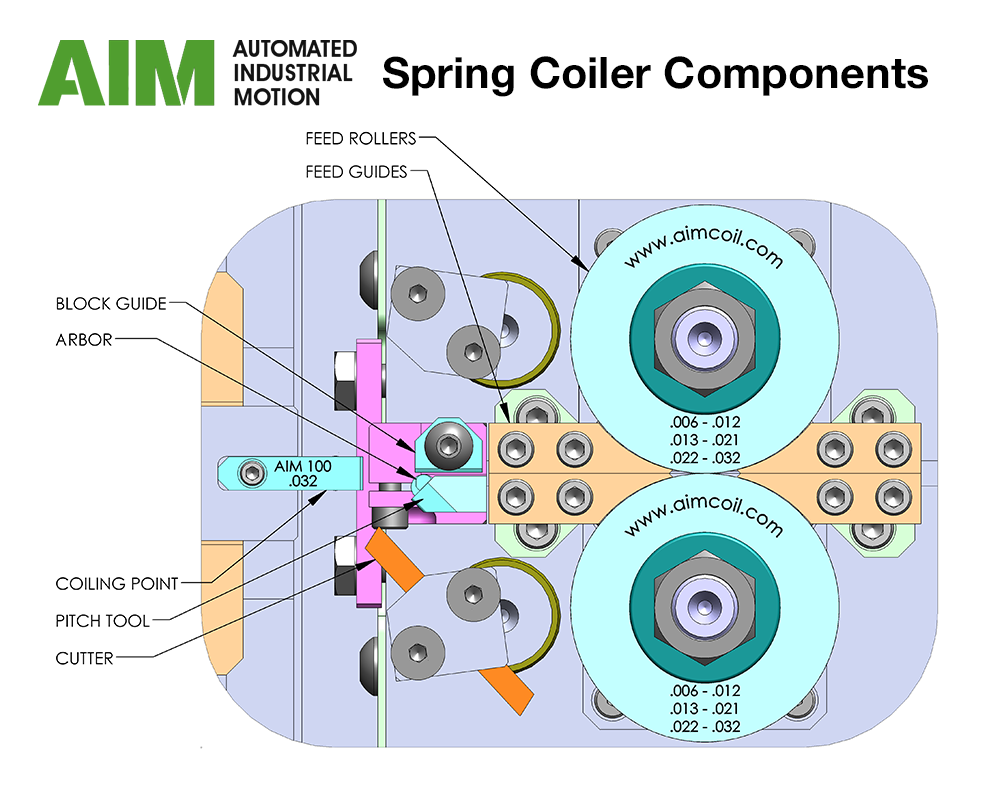

Spring Coiler Components

Spring coilers can be configured to produce a wide variety of spring shapes and sizes, but many of their basic components are the same across the board. Interchangeable cassette tooling allows for a high degree of versatility, so a single machine can produce many different springs. Even using the same tooling, operators can adjust spring parameters to a significant degree.

At Automated Industrial Motion, we manufacture single-point spring coilers capable of working with wire between .006” and .787.” In appearance, size and capability, there’s a big gap between our compact model, the AIM 100, and our heavy duty model, the AIM 4000. However, the components that make up the two coilers are analogous. The following spring coiler components comprise the functional characteristics of most single-point spring coilers, including our own.

Standard Spring Coiler Components

- Feed Rollers: These circular components are one of the most prominent features on many spring coiling machines. As they turn, they pull the wire from the reel and into the wire guides. Feed rollers often feature three grooves of different sizes, corresponding to the same grooves in the wire guides.

- Wire Guides: Wire guides are flat components containing grooves of varying size that match those on the feed rollers. The groove size doesn’t have to match the wire exactly, but it does have to be within a specified range. Wire travels through wire guides before reaching the block guide, the arbor or the coiling point.

- Block Guide: As wire exits the wire guides, it meets the block guide. This component ensures that the wire continues on the right path to the coiling point. The groove at the bottom of a block guide must be accurately machined to match the wire’s diameter.

- Arbor: At the same time that the wire passes through the groove of the block guide, it passes over and around the arbor. In single-point coilers, the arbor represents the third point of contact at the point of coiling. Spring physics demand at least three points to coil wire; dual-point coilers have a third point in the additional coiling point, and so the arbor is not as necessary.

- Pitch Tool: By sliding up and down and moving the wire along a sloped surface, the pitch tool precisely controls the pitch of the spring. Like the arbor, this component is also carefully machined to fit each job.

- Coiling Point: The coiling point is the component that pushes the wire into a coiled shape by deflecting its trajectory. Setup parameters determine exactly the angle at which the wire is deflected, which in turn determines the spring index, diameter and overall shape of the spring. One notable difference between spring coilers is the number of coiling points. See this post for an overview of single-point and dual-point spring coilers.

- Cutter: When a coil has reached its desired length, the cutter slices the wire to create a separate spring. Depending on the coiling direction, the cutter may be positioned above or below the arbor.

Optional Spring Coiler Accessories

Beyond the standard components, spring coiling systems often employ additional tools to ensure smooth operation and improve product quality. Optional spring coiler accessories include:

- Power Wire Payoff: Manual wire payoffs (or dereelers) can cause wire tension to vary as it travels from the reel into the spring coiler. By using power wire payoffs, spring manufacturers can ensure constant tension levels, which often results in more consistent springs.

- Wire Straightener: These systems straighten the wire before it enters the spring coiler. Various types are available, including roller straighteners and spinner straighteners. The goal of any wire straightener is to support more consistent coiling.

- Stress Relief Oven: When wire goes through the coiling process, it develops molecular stress that can lead to performance issues down the line. The solution is often heat treatment, which allows a new equilibrium to form inside the wire. Spring coiling systems can feed directly into a heat treatment oven for stress relief.

- Spring Grinder: The ends of coiled springs are sometimes ground off so that the spring can stand on a flat surface. Often, spring grinders are configured as double-disc grinders. In double-disc grinders, a plate holding a number of springs slowly rotates between two spinning discs that grind down the spring ends.

Using both standard components and optional accessories, coiling systems can be configured to produce a wide variety of springs and wire forms. Our own line of CNC spring coiling machines includes 7 models, capable of manufacturing springs with wire diameters of .006” to .787”. For more information, download our product brochure.