All About Variable Pitch Springs

Variable pitch springs are springs that do not have constant coil spacing. This type of coiling design offers a number of advantages, and a wide range of products depend on variable pitch springs to deliver optimal performance.

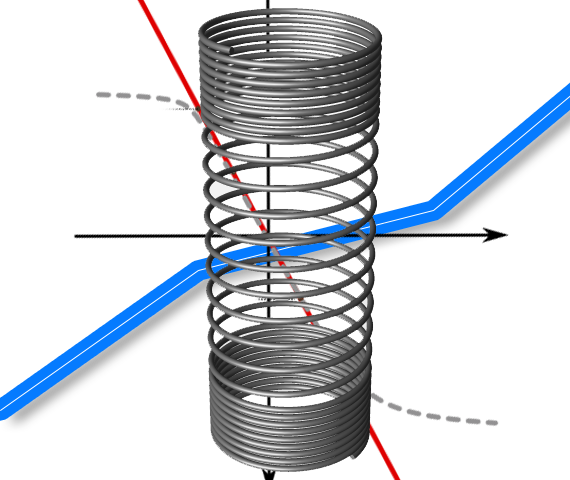

In order to understand variable pitch springs, it’s important to know two key spring parameters: pitch and rate. Spring pitch is the distance between two adjacent coils, measured from the midpoint of the spring material. Spring rate is the ratio of force required to deform a spring to the extent of deformity. In compression springs, spring rate measures how difficult it is to compress the spring; in extension springs, spring rate measures how difficult it is to extend the spring.

Variable pitch springs are employed when the manufacturer wants to control spring rate, so the two concepts are closely linked. Spring rate can also be controlled by adjusting spring diameter, but variable pitch springs can offer similar rate profiles while maintaining constant coil diameter.

Advantages of Variable Pitch Springs

Manufacturers find a number of advantages in the ability to vary spring pitch. For example, conical springs (and other types of variable diameter springs) can be made to deflect at a linear rate. Variable pitch can also be used to prevent coils from fully closing in “soft” springs, or springs with a low spring rate. Both extension and compression springs can sometimes benefit from the inclusion of several rows of closed coils, which still allows flexibility but prevents tangling.

A more technical advantage is the prevention of spring surge. Spring surge occurs when a spring’s natural frequency corresponds to the frequency of applied force, causing the spring to oscillate back and forth (similar to the way a slinky moves when held on both ends). Spring surge shortens the life of springs, and in some cases can cause immediate failure. By varying the spring pitch, manufacturers can prevent spring surge in high-frequency applications like valves and automatic weapons.

How Variable Pitch Springs Work

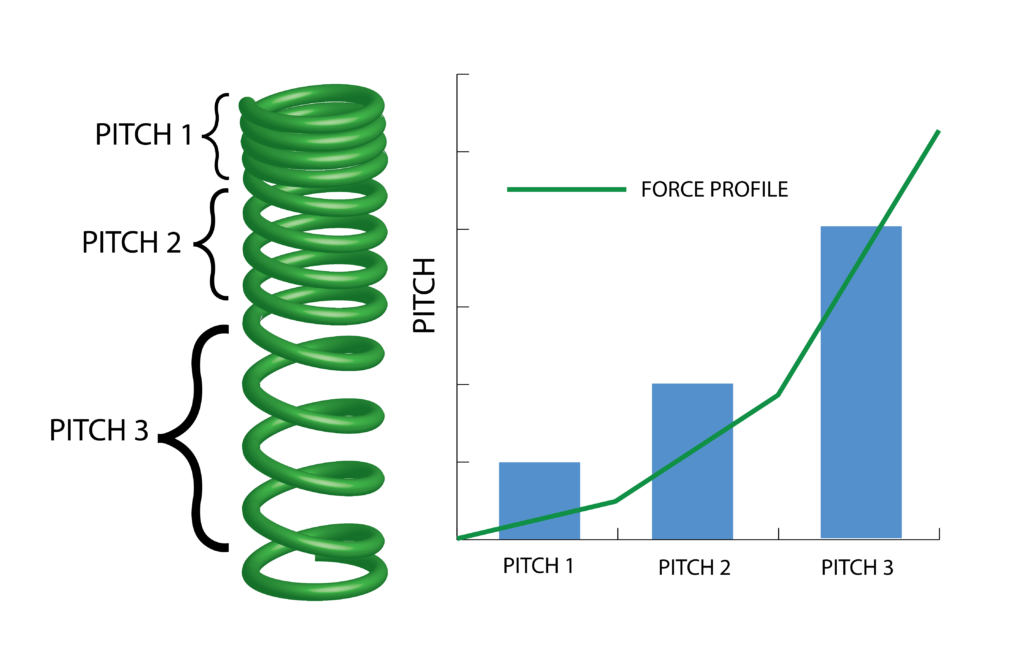

If coil diameter and wire diameter are both constant, springs with higher pitch (more distance between adjacent coils) require more force to deflect. In variable pitch springs, the lower-pitch coils deflect first, requiring less force. As applied force increases, coils with higher pitch begin to deflect and the observed spring rate also increases.

Variable pitch springs can be similar in performance to a stack of conventional springs, each with a different pitch. Before modern equipment made it possible to precisely manufacture variable rate springs, these stacks were much more common. However, given the ability to produce a single spring offering similar characteristics, manufacturers often trade multiple parts for a single, streamlined spring.

Uses for Variable Pitch Springs

- High-Performance Vehicle Suspension

In high-performance automobiles, suspension must absorb bumps and dips in the road while keeping the driver in control. Variable pitch springs can offer a soft ride without negatively affecting performance, especially when cornering at high speeds. - Commercial Vehicle Suspension

Commercial vehicles, like delivery trucks and passenger vans, need to provide smooth suspension under a variety of payloads. Variable pitch springs can be designed to offer similar performance under multiple tiers of deflection, corresponding to how empty or full the vehicle is. - High-End Mattresses

Functioning under the same principle, mattress coils also take advantage of variable pitch springs to create a softer, more responsive mattress that still provides a high degree of underlying support. - Valves

Because of their ability to minimize spring surge, variable pitch springs are often used in dynamic applications where the spring is rapidly compressed and decompressed at a rate close to the spring’s resonant frequency. Valve springs represent one such application.

Manufacturing Variable Pitch Springs

Using modern spring coiling equipment, variable pitch spring manufacturers can design and produce springs to match a wide variety of end-products. CNC controls, like our PC-based controls systems, make it easy to dial in pitch parameters alongside other characteristics like diameter and length. Spring manufacturers may choose to clearly delineate sections of differing pitch, or to produce springs with a planned rate of variation. PC-based controls allow operators to design any configuration.

In addition to standard compression-spring variables like wire diameter and end treatment, manufacturers of variable pitch springs must also consider:

- Spring rate: should the spring approximate linear force, constant force or otherwise variable force?

- Spring diameter: should spring diameter be constant, or is a conical, barreled, or hourglass spring more desirable?

- Resonant Frequency: in dynamic applications, at what frequency will the spring be compressed and decompressed?

With robust CNC spring coiling equipment, manufacturers can easily produce variable pitch springs with a wide range of custom parameters. AIM’s line of CNC spring coilers can be configured to manufacture compression springs and extension springs with nearly any pitch configuration.

Learn More

Take a look at these resources for more information on the springs and spring coilers discussed in this blog.