The Physics of Springs: How Manufacturers Design Springs That Work

Set a compression spring next to a leaf spring and you’ll see two very different objects, with not a lot in common on the surface. Springs come in a wide variety of shapes and sizes, but no matter how they look, they all work the same way. Every spring is an elastic object, meaning that it stores and releases energy. Spring design, and spring manufacturing, depends on a keen understanding of the physics of springs.

The spring manufacturing process, and spring manufacturing equipment, is a bit more complicated, but springs themselves are simple mechanisms that behave very predictably, as long as you know what to expect. By understanding the physics of springs, manufacturers can predict exactly how a spring will act in the real world, before they turn on the coiling machine.

Hooke’s Law: The Physics of Springs

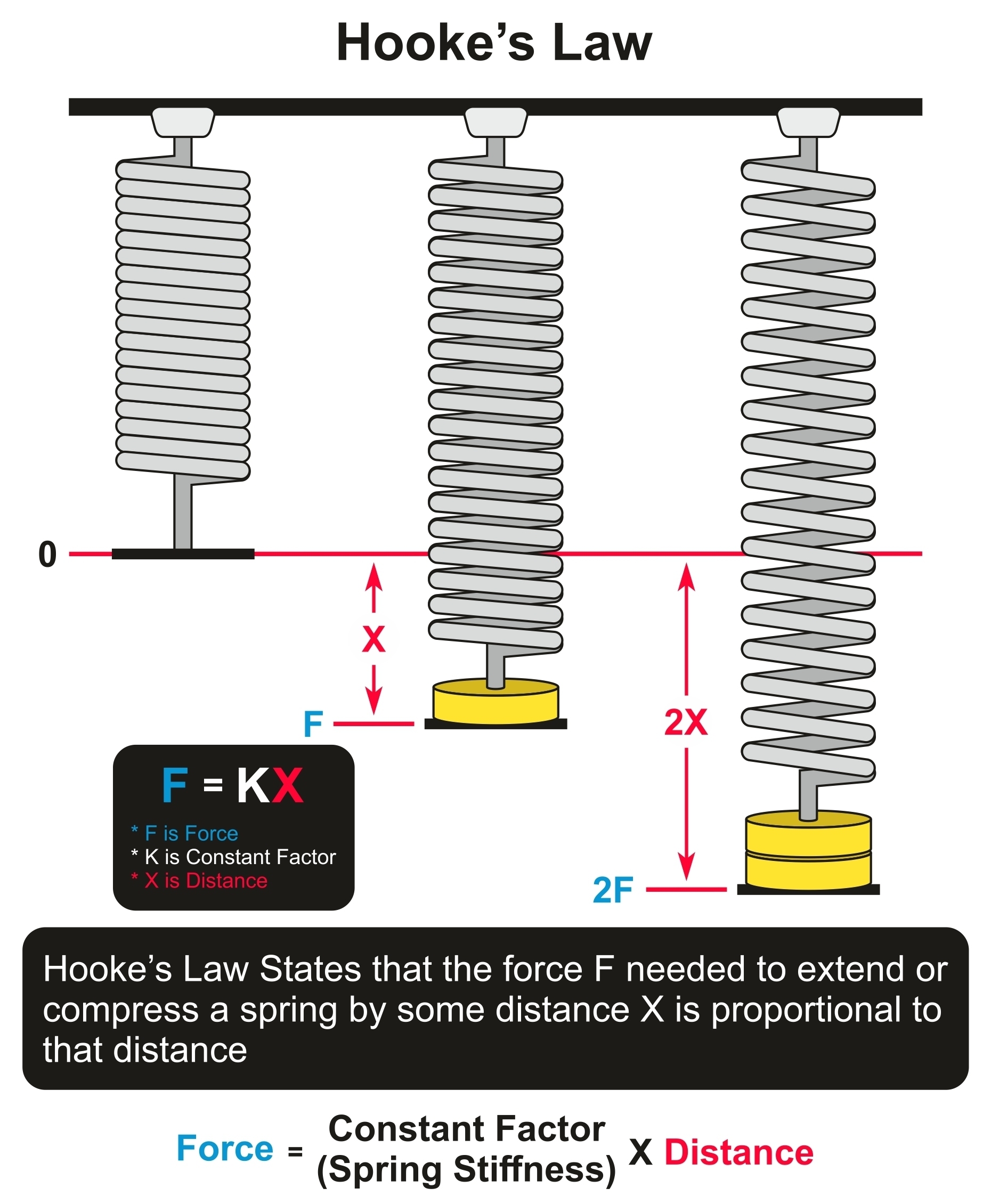

Beyond storing and releasing energy, another important aspect of the physics of springs is Hooke’s Law. Hooke’s Law states that the more you deform a spring, the more force it will take to deform it further. Using the example of a common compression spring, the more you compress the spring, the more force it will take to compress it further.

Beyond storing and releasing energy, another important aspect of the physics of springs is Hooke’s Law. Hooke’s Law states that the more you deform a spring, the more force it will take to deform it further. Using the example of a common compression spring, the more you compress the spring, the more force it will take to compress it further.

British Physicist Robert Hooke (pictured at right) first published the law in 1678, though he claimed to have known about it for nearly two decades. The law was simply stated in Latin, ut tensio, sic vis, which roughly translates to “as the extension, so the force.” The more modern, algebraic representation of the law is F=kX, where F is force, k is the spring constant, and X is the length of deformation.

If you look at a graph of the equation, you’ll see a straight line, or a linear rate of change for the force. Because of this trait, springs that obey Hooke’s law fall into the category of “linear force” springs.

The Spring Constant

The spring constant determines exactly how much force will be required to deform a spring. The standard international (SI) unit of measurement for spring constants is Newtons/meter, but in North America they are often measured in pounds/inch. A higher spring constant means a stiffer spring, and vice-versa.

The spring constant can be determined based on four parameters:

- Wire diameter: the diameter of the wire comprising the spring

- Coil diameter: the diameter of each coil, measuring the tightness of the coil

- Free length: the length of the spring when at rest

- Number of active coils: the number of coils that are free to expand and contract

The material making up the spring also plays a role in determining the spring constant, along with other physical properties of the spring.

Exceptions to Hooke’s Law

In the world of springs, there are several exceptions to Hooke’s Law. For example, an extension spring that’s extended too far will cease to conform to the law. The length at which a spring stops following Hooke’s law is called its elastic limit.

Variable diameter springs, like conical, convex or concave springs, can be coiled to a variety of force parameters. If the spring pitch (the space between coils) is constant, a conical spring’s force will vary non-linearly, meaning that it will not follow Hooke’s Law. However, spring pitch can also be varied to produce conical springs that do obey the law.

Variable pitch springs are a third example of a spring type that does not obey Hooke’s Law. Variable pitch springs are often compression springs with constant coil diameters, but varying pitch.

Constant force springs, in relation to Hooke’s Law, are often false exceptions. From their title and description, you would expect constant force springs not to follow Hooke’s Law. After all, if the force they exert is constant, how can the force change with the length of the spring? As mentioned in our constant force springs post, the material making up these springs actually does conform to Hooke’s Law. The difference is that the elastic portion of a constant force spring is only the part that is changing from coiled to straight. As the spring is pushed in or pulled out and the diameter of the coil changes, the force exerted also changes. This change, however, is often imperceptible because changes to the diameter of the coil are so small.

Using advanced AIM CNC spring coiling equipment, constant force springs can be designed so that the spring force can be kept constant or even be made to exhibit a negative gradient as the spring is extended. Negative gradients on the order of 35% have been accomplished.

Why Spring Physics Matters for Spring Design and Manufacturing

When manufacturers produce springs, they need to know how the spring will behave. It’s obvious that the same spring used for truck suspension wouldn’t work in a ball-point pen – but for many mechanical applications, minute differences in spring behavior will determine whether the system functions or not.

For example, springs are used to enlarge blood vessels in medical applications. If the spring constant is too high, or the wire too thin, the spring could cause a life-threatening rupture. On a larger scale, automobile suspension systems rely on extremely precise springs to provide shock absorption without destabilizing the vehicle at high speeds.

All spring design characteristics play a role in determining the useful applications for any given spring. When a manufacturer dials in the settings on their spring coiling machines, they aren’t just guessing. By understanding the physics of springs, manufacturers can ensure that they coil the right spring for the job.