Stress Relieving Springs

One of the most important steps in the spring manufacturing process is stress relief. I’m not talking about drinking chamomile tea or doing yoga (I’ll save that for another post). Stress relieving springs means applying physical processes that improve the molecular structures of springs, making them stronger, more consistent and longer lasting.

Stress relief is often carried out through heat treatment, but heat treatment is a much more general category of processes that are carried out on most metal products for various reasons. Stress relief is a specific type of heat treatment, carried out for the express purpose of reducing molecular stress in the product.

Why is stress relief necessary for springs?

When a shop or factory produces springs, they take wire that’s already been stretched and loosely coiled, and apply force to coil the wire into the shape of a spring. Settings on spring coiling machines determine the spring diameter, pitch and resting length of the spring. Once a spring is coiled, its resting shape is now the spring shape that it’s designed to be, but just because it’s ‘resting’ doesn’t mean that it’s free of stress.

In reality, the molecules that make up the wire are thrown out of whack by the coiling process. The coiling process has left the spring full of residual stress, internal stress that remains even when the object is resting. When springs are used repeatedly, residual stress can lead to defects, cracking, or a short working lifespan.

Stress relief allows a new equilibrium to form on a molecular level within the spring. For many springs, stress relief is a mandatory step in manufacturing. Without it, springs have a much greater tendency to change over time. Coil diameters grow, spring length gets shorter, torsion springs open farther (90 degrees will relax to 120 degrees, for example). Overall, springs that aren’t stress relieved often don’t perform as expected, and usually don’t last as long as their stress relieved counterparts.

How does stress relief work?

Stress relief is often carried out through heat treatment. Newly coiled springs are heated to a temperature just below the material transformation temperature, so that the wire becomes more malleable but does not start to melt or lose its shape. Then, the springs’ temperatures are slowly reduced until they reach room temperature. Too rapid heat reduction can result in additional defects, like cracking and deforming.

As the springs cool, their molecules rearrange into a more “comfortable” position. Outwardly, stress relieved springs differ very little from non-stress-relieved springs. However, there are often slight changes in wire diameter, coil diameter and initial tension as a result of stress relief. Spring manufacturers must compensate for these changes, finding the right settings through a combination of experience, calculations and trial and error.

Stress relieving springs as part of the spring manufacturing workflow

Stress relieving springs can take place in a heat treatment oven, which heats the springs to the optimal temperature and then controls their cooling rate. Heat treatment ovens are standard equipment in many metalworking facilities, but smaller shops and OEM manufacturers often outsource this step of the process.

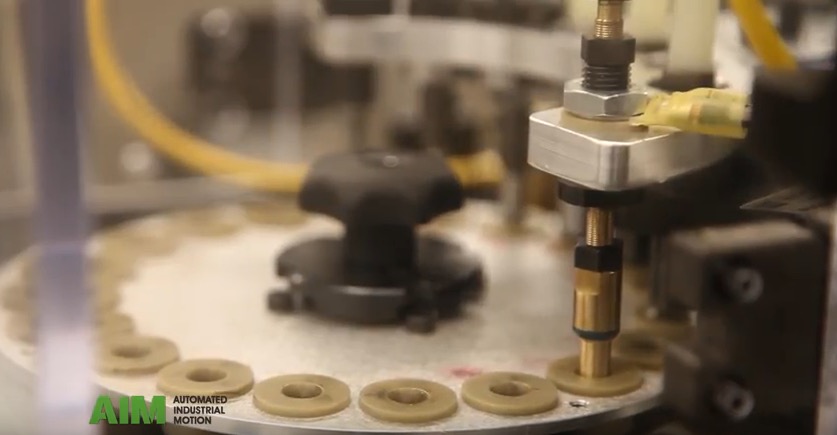

Another option is induction stress relief, which involves running an electric current through the springs. This process is useful in automation, where the cardinal rule is to never lose control of the part. By replacing a convection oven with an inductive current, each individual spring can be stress relieved while maintaining its place and orientation. The ultimate effect of induction stress relief is similar: the spring is heated to an optimal temperature to provide stress relief, and then allowed to cool.

Some spring manufacturing setups combine spring coiling, stress relief and quality control into one cell. For on-demand spring production, AIM offers a start-to-finish solution that allows manufacturers to coil springs, electrically stress relieve the springs, and then automate quality control for spring size and shape.