All About Constant Force Springs

We’ve already covered more basic spring types, like compression springs, extension springs and torsion springs, so now it’s time to take a look at something completely different.

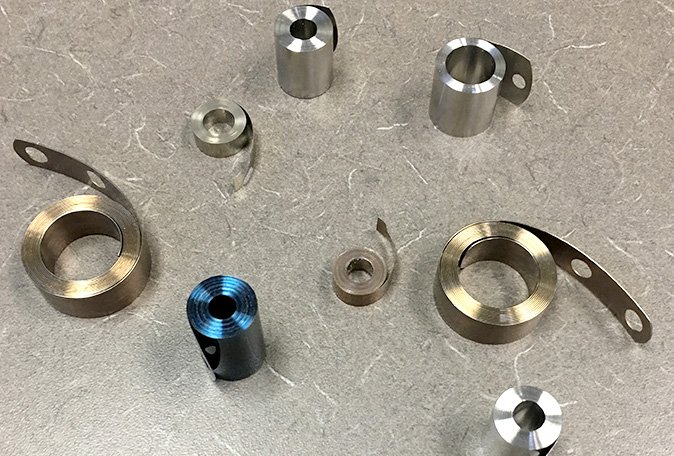

Constant force springs don’t have much in common, either in form or function, with standard helically wound springs. For starters, constant force springs are formed from pre-tensioned metal strips, rather than wire.

At their most basic level, however, constant force springs do exactly what other springs do. That is, they conform to Hooke’s Law. Hooke’s Law essentially states that when an elastic object is deformed, the force it exerts is directly proportional to the amount of the deformation. In other words, the farther you extend an extension spring, the more force it takes to pull it even farther; the more you compress a compression spring, the more force it takes to push it down even more.

In theory, a “constant force” spring would not obey Hooke’s Law, because the law mandates increasing force rather than constant force. In reality, the materials making up constant force springs do obey Hooke’s Law. However, constant force spring systems are still able to approximate constant force. In order to do so, the diameter of the coil must remain constant, or close to constant.

In standard constant force spring behavior, the user must first overcome the spring’s full load by extending the spring beyond 1.25 times its diameter. After that, the coil can be extended further by applying nearly constant force.

Common Uses for Constant Force Springs

Constant force springs’ unique qualities make them the perfect counterbalance for heavy moving parts.

One example is the door on a moving van. When you pull down an open door, it takes additional force to get the door going the first few inches–that’s because the spring’s full load (1.25 times its diameter) must be overcome. After that, the door slides down easily, with nearly constant force.

In addition to U-Haul doors, constant force springs are used in a wide variety of products. Some of the largest consumers are medical device manufacturers. MRI machines, dental X-ray equipment–and just about anything articulated and heavy–is equipped with constant force springs. Smaller constant force springs for medical devices are also part of syringes and drug infusers.

You’ll find plenty of constant force springs in everyday products as well: retractable key holders, retractable dog leashes, vacuum cleaner cord reels, seatbelts, window balance systems, interior blinds and point-of-purchase displays, to name a few.

Manufacturing Constant Force Springs

Constant force springs can be manufactured using the same spring coiling machines used for helical springs. The coiler will have to be modified to accommodate the flat strip of metal that makes up the constant force spring. AIM offers modifications for constant force spring manufacturing as part of their turn-key coiling system design services.

Once the equipment is calibrated, constant force spring manufacturers have to decide on a number of parameters before beginning production:

- Material, width and thickness of strips: these three parameters go a long way in determining the properties of constant force springs, much in the same way that wire material and diameter determine the properties of helical springs

- Initial load: the force that must be overcome in order to reach “constant” force

- Internal and External Diameter: the diameter inside the coil, which often surrounds a drum, and the diameter outside the coil

- End type: The outside ends of constant force springs often attach to another part, which will act directly to coil and uncoil the spring

Learn More

Click here to read about the AIM 1000, configured for constant force spring manufacturing.